DEMIX PLASMA POWER GENERATOR

Demix Group is aware of the environmental and social consequences of traditional landfills, so it has dedicated itself to researching real and practical solutions, finding plasma gasification as an alternative that has already been tested in several industrialized countries such as Canada, China, the United States, Germany, and Romania.

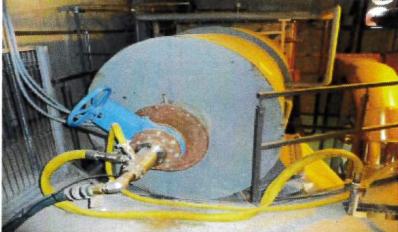

A plasma generator is a device that converts electrical energy into thermal energy carried by a gas. Plasma reactors allow almost any gas to be converted to the plasma state. The heat influx can be precisely and easily controlled.

The thermal energy carried by the gas can be used for heating, gasification, and chemical reactions, which take place in a reaction chamber located in front of the plasma generator. The gas used is generally part of the chemical reactions. Plasma generators transform between 85% and 90% of the electrical energy supplied to them into usable thermal energy.

Due to the very high enthalpy (energy density) of plasma, gasification and reforming reactions can take place in a rather small space.

The advantage of plasma technology is mainly the high temperature of the plasma jet, which can be used for two different purposes: a) support for gasification and fusion/vitrification of inorganic solid materials and b) decomposition of pyrolysis complex gases. into light hydrocarbon fractions.

WHAT IS PLASMA?

Plasma is the fourth state of matter, distinct from solids, liquids, and gases. When a gas is energized to high temperatures, its atoms lose electrons, creating a mixture of charged particles—this is plasma. Because of its unique properties, plasma is widely used in industrial processes that require high precision and efficiency.

ADVANTAGES OF PLASMA TECHNOLOGY

- High Efficiency: Plasma enables rapid and precise cutting and treatment of materials.

- Eco-Friendly: Reduces waste and lowers harmful emissions compared to traditional methods.

- Versatile Applications: Used in manufacturing, medical technology, and electronics.

- Cost-Effective: Enhances productivity while reducing material consumption and operational costs.

INDUSTRIAL APPLICATIONS

Cutting and Welding

Plasma cutting provides unparalleled precision for metals and other materials, making it indispensable in automotive, aerospace, and heavy machinery industries. Plasma welding, on the other hand, delivers strong and durable bonds.

Surface Treatment

Plasma gas is used to clean and activate surfaces, improving adhesion in painting, coating, and bonding processes. This is critical in industries such as packaging and electronics.

Plasma Gasification Process

The advantage of plasma technology is mainly the high temperature of the plasma jet, which can be used for two different purposes: Support for gasification and fusion/vitrification of inorganic solid materials. Decomposition of pyrolysis complex gases into light hydrocarbon fractions

OVERALL PROCESS

Counterflow Fusion Gasifier

Solid waste is fed from the top of the gasifier and begins its descent. The temperature in the upper part is between 300°C and 500°C, evaporating all moisture and volatile material. Preheated air is injected into the lower part of the gasifier, where the rest of the combustible material is gasified at 1500°C. Noncombustible materials, such as metals, glass, and other minerals, are melted together and used as a non-leaching metal slag alloy.

Plasma Reactor

The gaseous or liquid waste to be processed is injected directly into the reactor and mixed with gas from the gasifier. The gas and liquid enter a high-speed, high-temperature air jet (600-800 m/s and 3000-5000°C) generated by the plasma reactor. This air jet completely decomposes all hydrocarbons, including halogenated hydrocarbons like PAHs and dioxins.

In principle, any kind of material can be treated by this process. Inorganic compounds are recovered in the form of non-leaching slag and a metal alloy. The non-leaching slag can be used as a construction material, while the metal alloy can be melted down into products for sale or sent to a refinery.

Organic materials are converted into a fuel gas consisting mainly of CO, H2, N2, and some CO2. This fuel gas can be used directly in a gas turbine to produce electricity or in a boiler to generate steam or hot water.

DEMIX PLASMA POWER GENERATOR COMPONENTS

THERMAL AFTERBURNER

An important part of the process is thermal afterburning using plasma. The purpose of this process is the decomposition of complex hydrocarbons at the molecular level. This process takes place in four groups acting in a compact unit: the plasma torch, the mixing zone in the plasma jet, the reaction and settling zone and the ash outlet chute.

The extreme temperature of the plasma jet is used to solve the tar content problem in the syngas by causing the complex hydrocarbons to break down into basic molecules. The absence of tar makes it easier to clean the gas later in the process, making it even more efficient.

POWER PLANT

Electricity generation is a plant design process. In some cases, Demix Group recommends a mixed generation system where both gas and steam are used to achieve maximum efficiency.

Part of this generated electricity is used for the plant’s own consumption, generally 15 to 30%, and is known as parasitic energy. The surplus is connected to the electricity grid for sale.

Plasma technology is a game-changer, enhancing efficiency, sustainability, and innovation in various industries. Whether in cutting, welding, or advanced medical applications, plasma and plasma gas provide the precision and performance that modern industries demand. Furthermore, with Demix Group’s advancements in plasma gasification, waste management and energy production are revolutionized, offering an environmentally friendly and efficient alternative to traditional methods.

DEMIX PLASMA POWER GENERATOR'S

PRESENTATION

Request a quotation on Demix Innoshop!